AKROMID® NEXT SUSTAINABLE COMPOUNDS

PA 6.9, PA 5.6, PA 5.10, PA 11

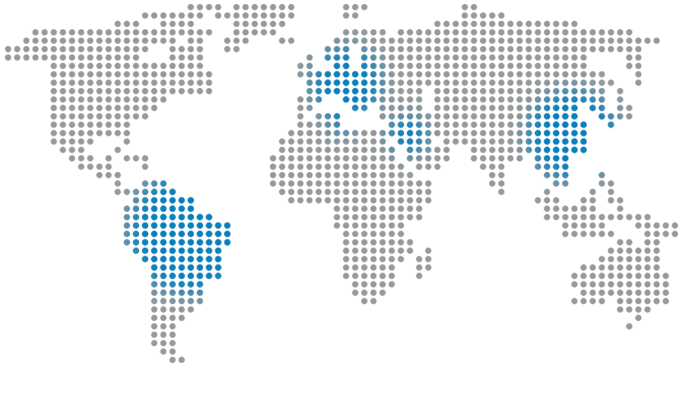

With AKROMID® NEXT, we offer innovative and sustainable alternatives to conventional nylons. This new product line has biobased, biomass-balanced or recycled contents. Some products are offered with ISCC PLUS or REDcert² sustainability certification.

AKROMID® ICF, AKROTEK® ICF, AKROLOY® ICF

Carbon Fibre Reinforced

Carbon-fibre-reinforced compounds drastically reduce the weight of high-strength components.

AKROTEK® PK

Polyketone

Constant mechanics under changeing climatic coditions? Our PK compounds could be just right for your application.

PRECITE®

PBT / PET and Blends

Thermoplastic polyesters are based on polybutylene- or polyethylene- terephthalate, (PBT) or (PET) and have a unique combination of properties to cover the high requirements of a variety of complex applications.

AKROMID® FR

Flame-Retardant Compounds

Selection of polymers for applications requiring flame-resistant plastics.

AKROMID® T

Polyphthalamide

Modified for higher performance, our PPA compounds deliver more. Discover how much they can do for you.

AKROMID® LITE

Polyamide/Polypropylene

Find out how low-weight PA and PP products are meeting the growing demand for reduced weight.

AKROMID® A / B / C

Polyamide 6.6 / 6 and Blends

This is one of our most versatile plastic compounds. It is sure to suit all your application needs, no matter how demanding.

AKROMID® HI

PA 6.6, PA 6, PA 6/6.6 Blends

Tough and shock-resistant polymer blends for high-demand applications.

AKROMID® RM

PA/PBT-Blends

The polyamide with reduced moisture absorption, AKROMID® RM is available in mechanical grades.

AKROMID® LGF, AKROTEK® LGF, AKROLOY® LGF

Long Glass Fibre

Long-glass-fibre-reinforced compounds are ideally suited to high-load applications.

English

English Chinese

Chinese