As the topic of lightweight design has a great impact on the product development of its compounds, AKRO-PLASTIC made this theme the focus at K 2016 in Düsseldorf.

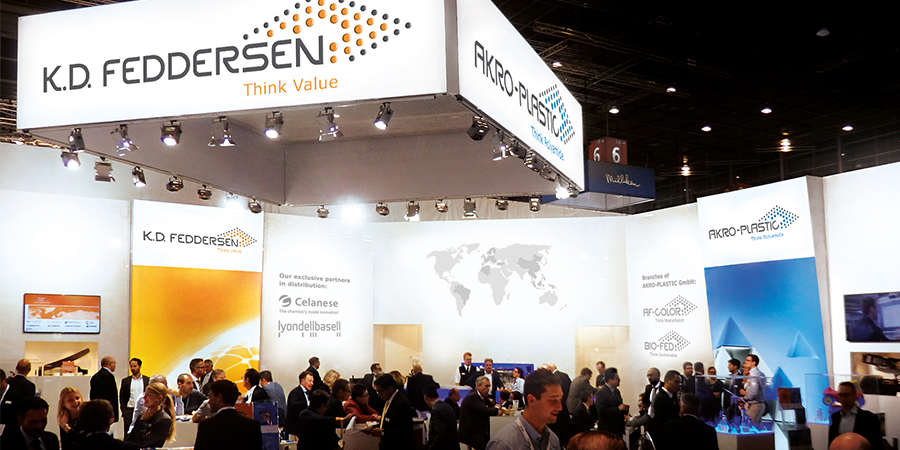

Together with its sister company, the distributor K.D. Feddersen, and their branches AF-COLOR and BIO-FED, AKRO-PLASTIC and its international sales team presented many new developments and improvements to existing products.

Together with Plasmatreat GmbH, AKRO-PLASTIC presented a live demonstration in the Plasmatreat exhibition space to showcase the latest innovation, which ensures superior adhesive bonding between metal and plastic. The demonstration featured a stainless steel hook integrally injected with AKROMID® B3 GF 30 1 PST black (6647). The enormous public interest aroused by this project shows that this topic had yet to be satisfactorily resolved until now.

There was also a live demonstration with the cooperation partner PME Fluidtec. Here, a clutch pedal was made from the carbon fibre reinforced polyamide AKROMID® ICF using water injection technology. A perfect example of why lightweight design and strength are not mutually exclusive.

New products such as AKROLOY® PARA ICF 40, a polyamide blend featuring extremely high strength and also very good surfaces, or the long fibre reinforced semi-aromatic materials AKROLOY® PA LGF 50 and 60 enjoyed high demand, according to the compounder.

"The great positive response from visitors confirms our conviction that lightweight design will be the new trend in the coming years," says Thilo Stier, Head of Sales and Innovation at AKRO-PLASTIC.

AF-COLOR, the masterbatch specialist within the Feddersen Group, forged many new contacts, especially in the packaging sector. These products were very well received in Eastern Europe as well as outside Europe, e.g. in Mexico. The standards and commodities from the black and additive masterbatch portfolio were particularly sought after there. According to Dirk Schöning, Head of Sales at AF-COLOR, German packaging customers continued to value color concentrates for film applications with top dispersing quality. "Our customers are always impressed by our potential as a comprehensive solutions provider," says Mr Schöning. "With our access to masterbatch, polymers and compounds, we have a significant advantage over competitors." According to Mr Schöning, the K exhibition is also increasingly attracting masterbatch manufacturers.

BIO-FED, specialised in biodegradable and/or bio-based plastics and the most recent member of the Group of companies, has also rated its premiere in Düsseldorf as a complete success. "I am delighted that the topic of bio-plastics now has such a wide reach and has become the focus of attention," says Dr Stanislaw Haftka, Head of Sales at BIO-FED.

"The economic expectations of our booth visitors were consistently positive, which is also positive for our future business development," says Leander Bergmann, Head of Marketing at AKRO-PLASTIC.

English

English Chinese

Chinese